The robot I intend to build will be a 4WD bot with a skid steer system so to do this best I have opted to build 2 a controller system moulded around a 4QD DCI111. (A DCI111 converts radio signals into useable signals) Because of this the inputs on my controllers have to be similar to the 4QD units. The next things to consider are the motors that I will be using. Bosch 750’s seem to be quite popular (so are ford escorts and they are crap) so I will just go ahed and use the many starter motors that I have lying around. This results in

more

DC Motor Control & Interfacing Circuit

A permanent magnet DC motor responds to both voltage and current. The steady state voltage across a motor determines the motor’s running speed, and the current through its armature windings determines the torque. Apply a voltage and the motor will start running in one direction; reverse the polarity and the direction will be reversed. If you apply a load to the motor shaft, it will draw more current, if the power supply does not able to provide enough current, the voltage will drop and the speed of the motor will be reduced. However, if the power supply can maintain voltage while supplying the current, the motor will run at the same speed. In general, you can control the speed by applying the appropriate voltage, while torque is controlled by current. In most cases, DC motors are powered up by using fixed DC power supply, therefore; it is more efficient to use a chopping circuit.

more

PWM D.C. motor drive Circuit

This circuit is a very compact switching regulator for small DC motors. I use it for my small printed circuit board drill (18 Volt, 1.5 Amp), but it is suitable for many other applications (e.g. 12V DC halogen dimmer).

more

Back EMF PM Motor Speed Control Circuit

A 12 V control supply and a TRW BL11, 30 V motor are used; with minor changes other motor and control voltages can be accommodated. For example, a single 24 V rail could supply both control and motor voltages. Motor and control voltages are kept separate here because CMOS logic is used to start, stop, reverse and oscillate the motor with a variable delay between motor reversals.

more

Bidirectional DC Motor Speed Controller

This kit allows controlling the speed of a DC motor in

both the forward and reverse direction. The range of

control is from fully OFF to fully ON in both directions.

This kit overcomes both these problems. The direction and

speed is controlled using a single potentiometer. Turning

the pot in one direction causes the motor to start spinning.

Turning the pot in the other direction causes the motor to

spin in the opposite direction. The center position on the

pot is OFF, forcing the motor to slow and stop before

changing direction.

more pdf

PWM DC Motor Speed Control

The left half of the 556 dual timer IC is used as a fixed frequency square wave oscillator. The oscillator signal is fed into the right half of the 556 which is configured as a variable pulse width one-shot monostable multivibrator (pulse stretcher).

more

DC Motor Controlled with PWM Resources

Here is a description of the driver circuit. It's based on the Microchip AN531 Application Note titled "Remote Positionner". The circuit given in the application Note do not work , so this is a correction of the circuit:

more

DC MOTOR CONTROL USING A SINGLE SWITCH

This simple circuit lets you run a DC motor in clockwise or anti-clockwise

direction and stop it using a single switch. It provides a constant voltage for

proper operation of the motor. The glowing of LED1 through LED3 indicates that

the motor is in stop, forward rotation and reverse conditions, respectively.

more pdf

Bidirectional DC motor speed control using Pulse Width Modulation

The simplest method of implementing microcontroller controlled H-bridge drive of a reversible DC motor is to buy one of many commercial H-bridge IC's availible on the market. These can be purchased separately as an H-Bridge with a separate H-Bridge controller IC, or as an all-in-one IC. Unfortunately, there are several hurdles that sometimes frustrate this approach. Students often find these devices hard to find, as they are apparently in high demand. Secondly, many of these devices have limited current drive ability, such that larger DC motors end up running sluggish or stalling easily. One option is to build your own H-bridge from discrete parts, as shown below.

more

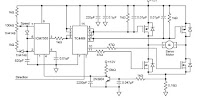

Low-Cost DC Motor Speed Control with CMOS ICs

Two low-cost CMOS ICs manage a 12 VDC, current-limited speed

control circuit for DC brush motors. The circuit design (see

Figure 1) uses PWM (pulse width modulation) to chop the effective

input voltage to the motor. Use of CMOS devices gives the benefits

of low power, minimal heat and improved longevity. The overall

design is simple, inexpensive and reliable, and is useful in applications

such as embedded DC motor control where efficiency,

economy and performance are essential.

more pdf

Digital Speed Control by Anthony Psaila

My design is based around three parts:

1. The controller board. This is a fully digital circuit that takes the 1ms to 2ms pulse from the receiver and converts it into a pwm train at 1Khz. It uses six cmos ics (74hc and 40 series) and a 4Mhz crystal clock. The only other components are one resistor and two capacitors to complete the crystal clock and a capacitor across the supply for smoothing. This was built on a printed board measuring 2 x 2.25 inches using standard components (on the boat there was no shortage of space). If surface mounted devices are used, the lot can be crammed into a much smaller space. The circuit can give a resolution of 128 steps (7bits). Some day I will expand it to have reverse function, but this is better done by a switcher circuit supplied from another channel (my reciever can give 7 channels and I am using only two at present).

more